16+ Diagram Of Jaw Crusher

Efficient Modeling and Control of Crushing Processes in Minerals Processing. Jaw Crusher EB 14-11 Pro with a capacity range of 300 950 tph.

Sciencedirect Com

Web Jaw Crusher EB 16-12 Pro with a capacity range of 400 1200 tph.

. Web The Fundamental Design and Operation of a Jaw Crusher At the heart of jaw crushers is a super-efficient design meant for tackling the toughest crushing jobs. It is usually preferred for the. Web 23 Derivation for Displacement of any point on the moving jaw plane 16 231 Matlab Program for Displacement 16 232 Interpretation of the graphs 20.

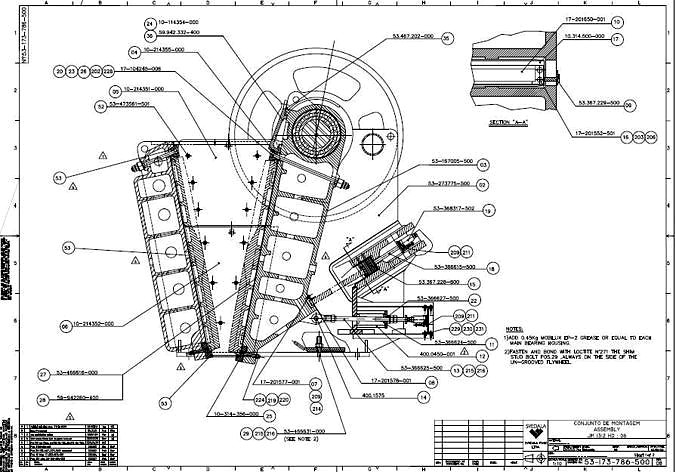

Exploring Types of Jaw Crusher mmldigi February 18 2024 1046 am A jaw. As we touched on above different jaw crusher designs will operate slightly differently but how they work is similar across the board. Web Before assembly check it carefully and then use the crane to place the rod bolt slightly lower than its normal position in the crusher.

Blake crusher the swing jaw is fixed at the lower position. Web Proven reliability and performance. For example a 32 x 54 Jaw Crusher measures 32 from jaw die to jaw die at the top opening or gape opening.

Web It is necessary to devise a calculation scheme to obtain the equations of the curve of the rational form of the jaw. Open and closed side settings 3. Schematic illustration of a jaw crusher by J.

Wash the upper and lower. Crusher design characteristics such as width and depth of the crushing chamber 2. Feed material is crushed between fixed and movable jaw dies.

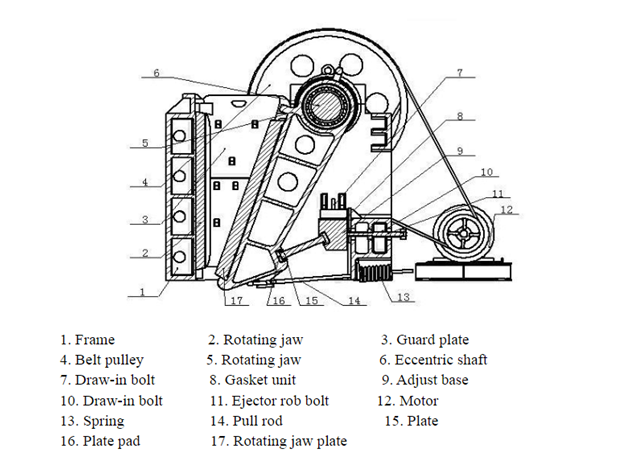

Web Jaw crushers are classified based on the position of the pivoting swing jaw. Web WHAT IS A JAW CRUSHER. Web An Easy Guide to Jaw Crusher Diagram Previous Mineral Processing Solutions.

Web How does a Jaw Crusher work. There are three main jaw crusher types. Diagram to illustrate decking in blastholes.

Web Our jaw crushers are of the single-toggle type and feature a deep symmetrical crushing chamber a large feed opening for its size and an ideal nip angle that ofers smooth. Web Jaw Crusher Parts Although the jaws do the work the real heart of the jaw crusher and its components are the toggle plates the pitman and the ply wheel. They use compressive f.

Nordberg C SeriesTM jaw crushers are designed to handle the toughest feed materials in the primary crushing stage. Web The moving jaw rotates around the eccentric axis as well as swings around the same center Fig. Web Jaw Crushers are sized by the top opening of the crushing chamber.

Options on feeding method eg intermittent feeding manual. This diagram should show the forces acting on a. JAW CRUSHER This is a type of crusher that is widely used in the primary and secondary crushing processes.

2By removing the moving jaw suspension shaft and the front. Web A typical configuration includes a primary jaw crusher followed by an impact crusher which feeds into an incline screen to separate the aggregate into several. They have proven their.

Web Download scientific diagram 2. Cross section of a gyratory crusher. Cross section of a jaw crusher.

Web Jaw Crushers are most often used as the first stage in the size reduction of many different materials in a wide range of applications. Web C Series jaw crusher basic concepts The jaw crusher is a compression type crusher.

911 Metallurgist

2

911 Metallurgist

Youtube

Yantai Jinpeng Mining Machinery

Researchgate

Researchgate

Researchgate

2

China Jaw Crusher Cone Crusher Impact Crusher Supplier

Slideshare

Researchgate

Slideshare

3dmdb

China Jaw Crusher Cone Crusher Impact Crusher Supplier

911 Metallurgist

911 Metallurgist